Menu

Menu Waste water in the corrugated board industry

Corrugated board/cardboard is printed almost exclusively with aqueous inks.

Some of these inks contain up to 10 % (water-dilutable) solvents. But even solvent-free inks contain binders (resins), pigments (colouring substances) and additives. These lead to a considerable pollutant load in the waste water.

The possible pollutant load of an ink wastewater results from the composition of an aqueous printing ink:

20 - 30 % pigment

15 - 25 % binder

0 - 10 % alcohol or water-soluble solvents

40 - 50 % water

5 - 10 % additives

At the end of the work, the parts that have come into contact with ink, in particular the rollers, ink trays and the ink supply system, must be cleaned. Another sub-stream is the sizing water, which must be completely or partially mixed with the printing ink waste water and treated in the waste water treatment plant. Glue waste water is highly contaminated with organic substances such as maize, potato or wheat starch.

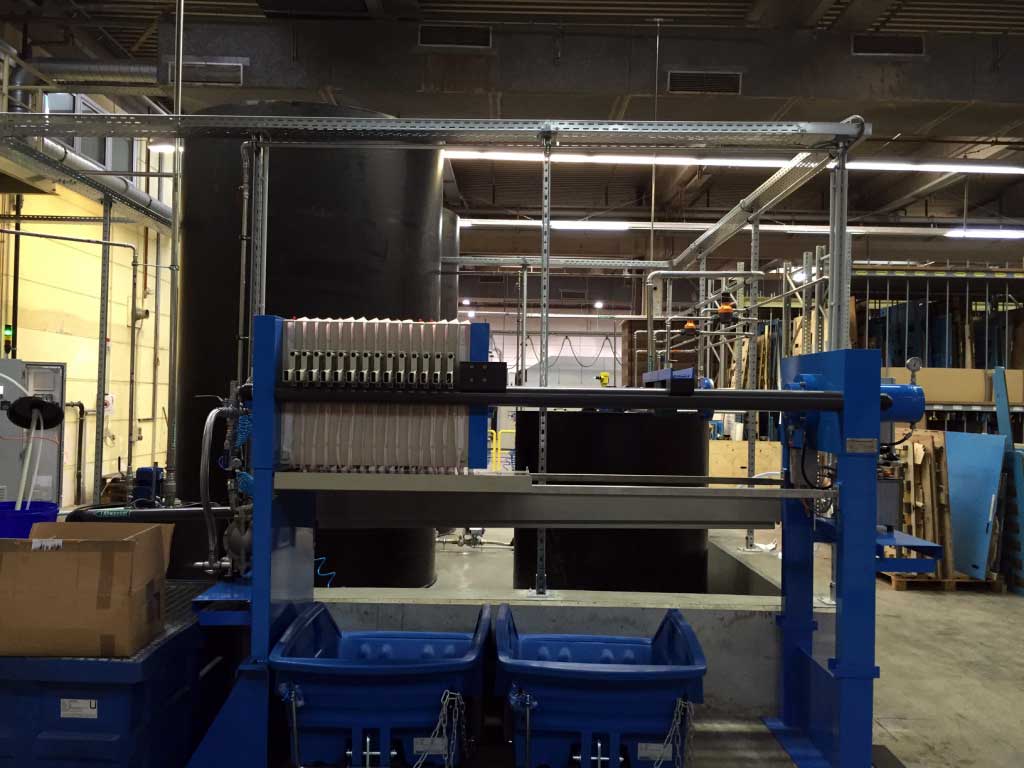

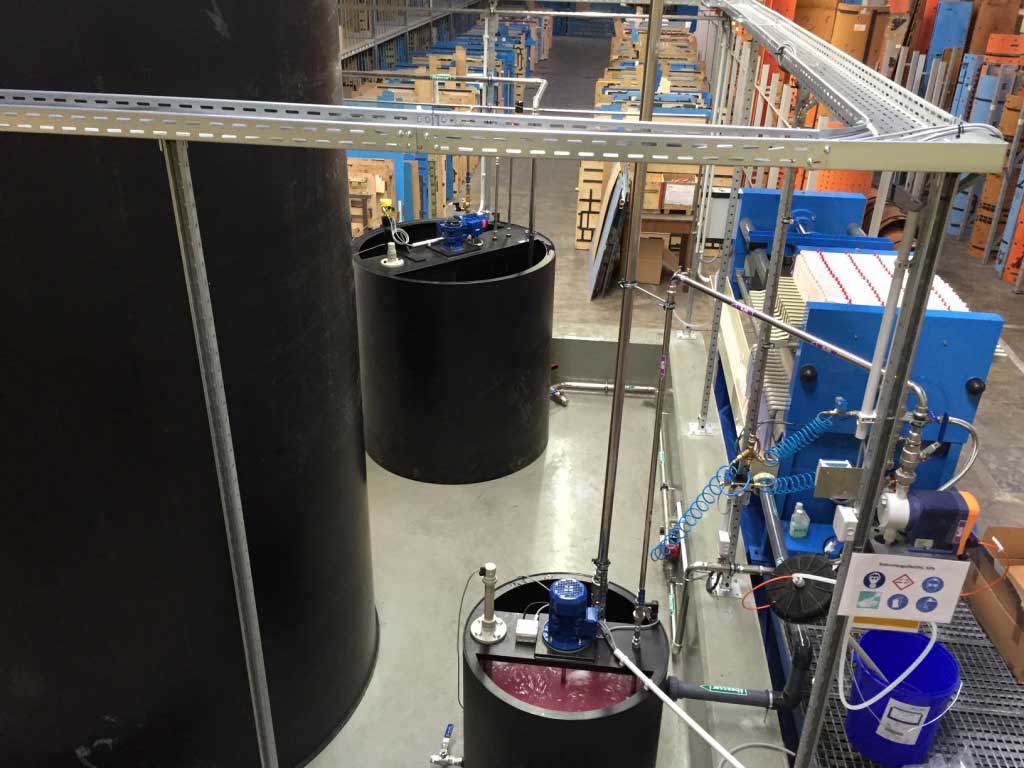

Our solutions

Full service from BRAND Wassertechnik

With our decades of experience, especially in the corrugated cardboard industry, we can offer you a customised, high-quality wastewater treatment solution.

From consulting, planning/design and plant construction to official authorisations, environmental consulting and employee training, our know-how provides you with an all-round carefree package. Of course, we won't leave you on your own: with maintenance, service and the supply of chemicals, we help you to operate your pressurised wastewater system as efficiently as possible.

Your contact

Marcus Färber

+49 (0) 2150 - 70 69 69 8

info@brand-wassertechnik.de

- 0

- 1